XCMG used luffing tower crane XGL300-18S is being dismantled down, only did a site project, the performance is very excellent, the machine is very new.Yueyang machinery first time to take it down, do our stock machine, professional service to our customers to provide luffing tower crane first choice.

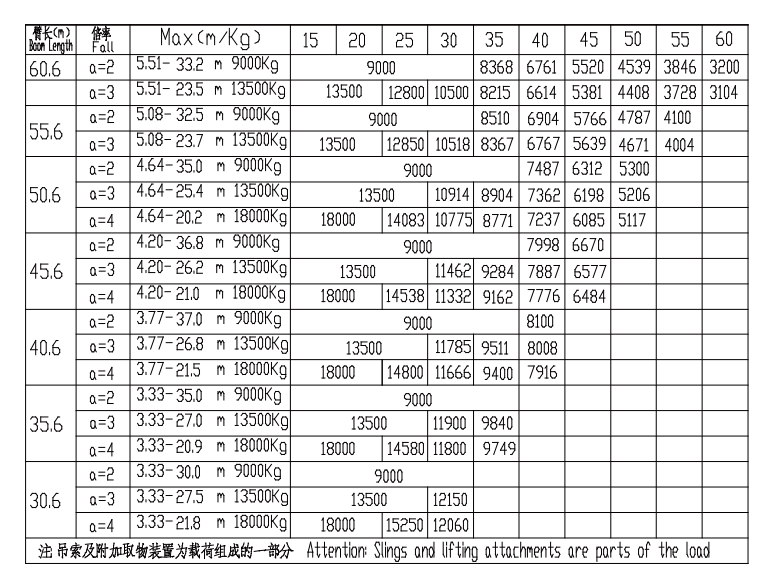

| Project | Unit | XGL300A-18S |

|---|---|---|

| Boom Length/Load at Boom End | m/t | 60/3.2 |

| Rated Load Moment | t·m | 300 |

| Maximum Lifting Capacity | t | 18 |

| Maximum Independent Height | m | 46.1 |

| Maximum Attached Height | m | 199.1 |

| Hoisting Rope Capacity | m | 805 |

| Maximum Hoisting Speed | m/min | 100 |

| Luffing Time (15°~85°) | — | ≤2.5 min |

| Slewing Speed | r/min | 0~0.7 |

| Hoisting Power | kW | 67 |

| Luffing Power | kW | 45 |

| Slewing Power | kW | 2×7.5 |

The industry’s first high-strength cold-bent steel application, lighter boom, better lifting performance than other manufacturers in the same industry, and the lightweight level is at the leading level in the industry;

The whole machine is equipped with 8.8-10.9 grade Dacromet high-strength bolts, which are higher in strength, stronger in rust resistance, and longer in service life;

The structural parts adopt powder electrostatic spraying technology, automotive-grade coating level, no fading in 2 years, no rust in 5 years;

The whole machine platform is made of aluminum alloy and will never rust;

For the first time, the design concept of the cab in the automotive field was introduced into the tower crane industry, and the electrophoresis treatment process was adopted to achieve a ten-year rust-free cab;

The air-conditioning outdoor unit is built-in, and the overall safety Installation and transportation can avoid damage to the external machine and reduce the risk of outdoor installation and maintenance operations;

The modular hoisting technology of the whole machine greatly improves the installation and disassembly efficiency by 20-30%;

The full frequency conversion control method realizes the flexible operation of each mechanism without impact, and is green, efficient and intelligent;

The industry-leading load-following speed function and worm speed control technology meet the needs of prefabricated buildings;

For supporting parts, relying on national quality inspection institutions, the three-level coverage of product testing range is achieved, and batch professional testing of key parts such as raw materials, high-strength bolts, and pins is achieved;

All supporting parts of the whole machine are from the top two supporting manufacturers in the industry.

If you have any questions/suggestions , please feel free to inform us. Your valuable information are highly appreciated.